CONSULTING, DEVELOPMENT, PRODUCTION, FINISHING, LOGISTICS – ALWAYS CUSTOMER AND PROCESS FOCUSED – ALL FROM A ONE-STOP SHOP

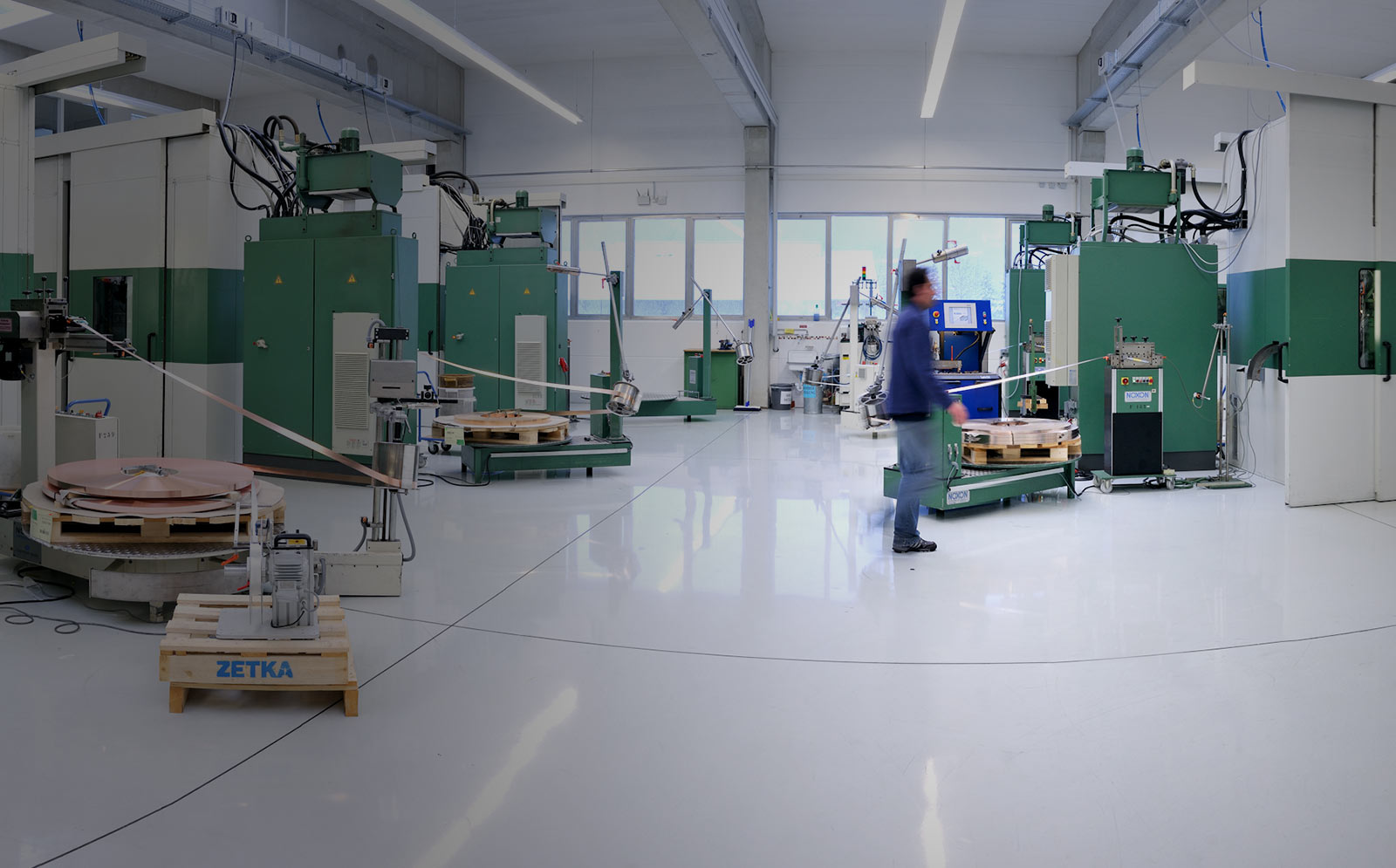

Thanks to our modern and flexible machine park, ZETKA provides a broad spectrum of services. But high-performance systems by themselves do not produce high-precision parts. Therefore, we rely on our employees' experience, professional knowledge and wealth of ideas. Each day, they work to ensure that our customers around the world are satisfied.

Embracing challenges while at the same time remaining focused on what can be done in processes that are reliable and stable. This is always at first aspect we consider when we are asked for something or talk with a client. Benefiting from cutting-edge expertise in forming techniques, our specialists ascertain whether your stamped, cold or warm-formed part can be manufactured and let you have answers to complex questions.

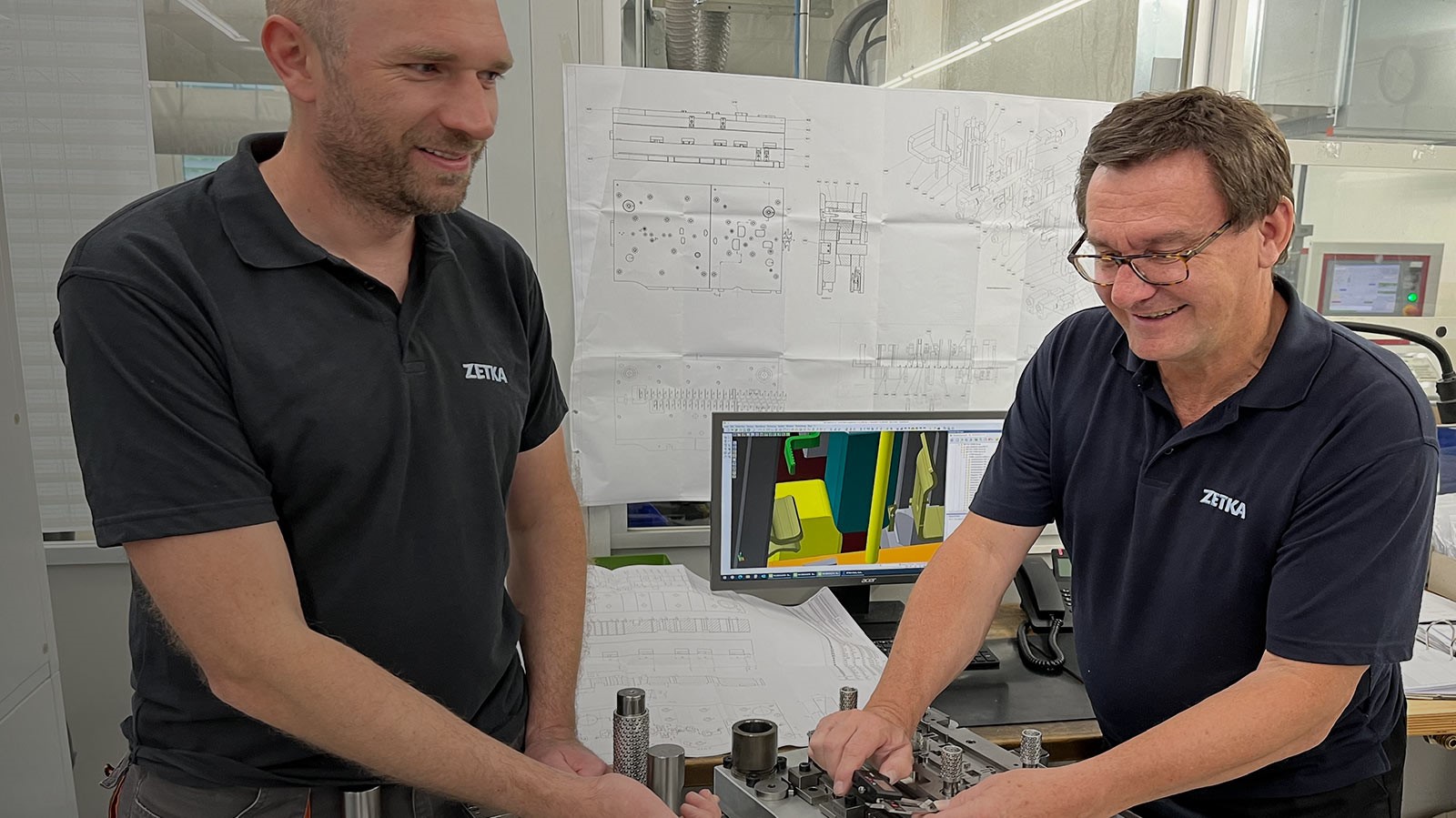

We develop and optimise solutions in close cooperation with our clients – focusing on customers' specific needs, cost efficiency and ingenuity. Benefit from our engineers’ expertise.

We provide individually tailored, professional project support as well as smoothly coordinated communication throughout the entire project term. Perfectly combining experience, ingenuity, creativity, passion and trust, we achieve the targets that are set to maximise the customer's business success.

Given our high-performance toolmaking operation and in close cooperation with our partners, we are reliably in a position to produce initial sample parts for all of our customers' projects in a very short time.

Whether preliminary visual samples or initial working parts leading to the first pre-production part made of volume-production materials, we are at your side throughout the entire product development process.

For this purpose, we set store by tried and proven erosion technology, laser technology as well as by micro waterjet cutting. We can also draw on numerous auxiliary tools for bending operations.

Particularly in the BIZON® press-fit zone we use pre-stamped strips under volume-production conditions for producing sample parts.

A successful project often only starts out from an idea or simple sketch. Our many years of experience helps us assist our customers in designing products, optimised for the best possible results in production. Working systematically, our experts find solutions to exacting challenges and meet whichever requirements the customer demands: with the right tool concept for the quantities needed!

Customer success begins as early as configuring the tool concept. Forward-thinking tool design and machine setting options for volume production form the basis for an effective production process. Short channels between design and toolmaking let us respond to changes at any time.

We design solutions using VISI CAD in the 3D system. Workstations are interconnected with the CAM stations and the machine tools. Our toolmakers have access to design data at all times.

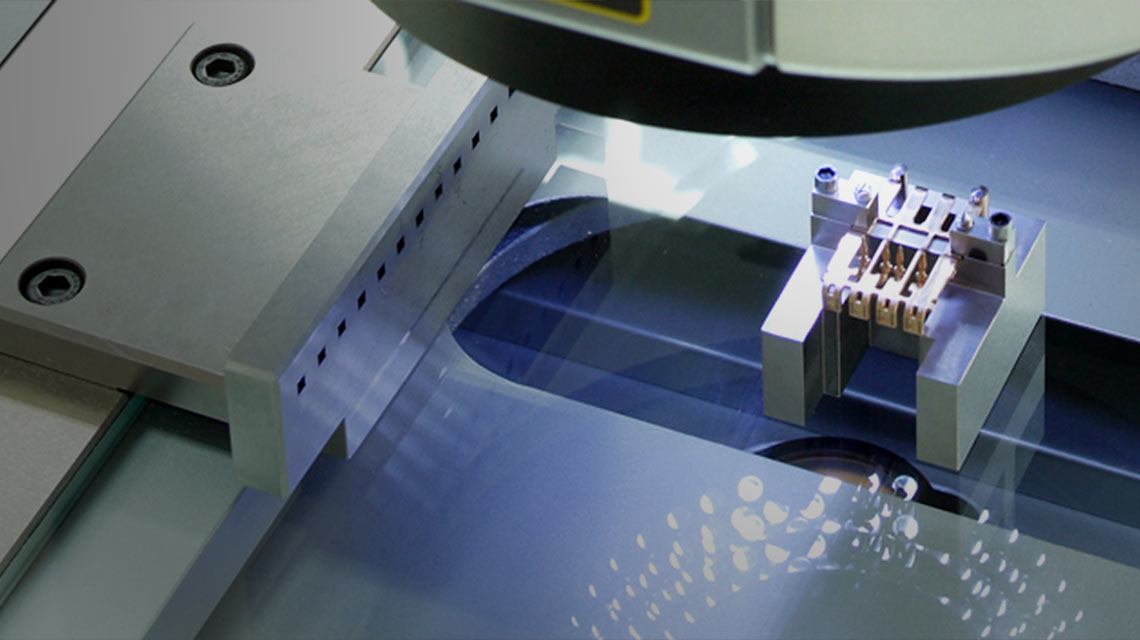

State-of-the-art 5-axis machining centres, robot-assisted erosion machines, cutting-edge surface and profile grinding machines as well as the very best materials in tool-making guarantee compliance with the tightest of tolerances and a consistently high level of quality throughout the product life cycle.

Making components in our fully air-conditioned tool-making activity guarantees the dimensional accuracy of every tool we produce.

In short: we give everything for the highest level of precision and perfection for your volume-produced parts and aim to excel in everything we do!

Production

Complementing each other, our three technologies of stamping, stamping and bending and cold heading mean we can offer a unique combination of manufacturing expertise.

Our production facilities are right on the cutting edge and, besides conventional drives, we are increasingly using servo drives or individual servo axes to address complex challenges.

The entire machine outfit, including highly automated periphery and all aspects of the production process, is organised to ensure the optimum flow of materials and products.

Our production facilities –ideally positioned with cutting-edge machines

- 1 Bruderer BSTA 200 stamping press

- 7 Bruderer BSTA 300 stamping presses

- 5 Bruderer BSTA 510-125B high-performance stamping presses with a press force of 50 tonnes

- 1 Bruderer BSTA 410-110B high-performance stamping press with a press force of 40 tonnes

- 1 Andritz-Kaiser stamping press KSTU 1600-17.5-3G-PR

Depending on material, we process strips in widths of up to 170 mm and in thicknesses of 4.0 mm. Wires in a maximum diameter of 2.5 mm. The following materials are used for most of our products:

- Copper and copper alloys, such as K88,K75, K65, K55; L49, Cu ETP, Cu DHP

- Bright and surface-finished bronze, such as CuSn6, CuSn8

- Bright and surface-finished brass, such as CuZn37

- New strip silver, such as CuNi9 Sn2

- Beryllium alloys, such as CuBe2

- Aluminium, such as AlMg3

- Spring steel, unhardened and hardened, such as C67

- Stainless steels, soft and spring-hard, such as 1.4301, 1.4303, 1.4571 and 1.4310

Parts cleaning

Exacting demands are placed on cleaning industrial parts. The cleanliness of parts is relevant to subsequent processing operations and also ensures the functionality and quality of the product at the customer. From Pero, one of the most modern and environmentally friendly parts cleaning systems with ultrasound, integrated circulating distillation, filter systems, pre-cleaning stages, 2-chamber cleaning system and steam cleaning enables us to supply stamped parts that are free of oil, grease and particles and meet all of the requirements commonly defined by both the electronics industry and the automotive industry. We provide verification on the basis of laboratory measurements in line with VDA 19 or customer standard requirements during the sampling phase or by means of in-process measurements.

Matching individual cleaning sequences to suit the particular application lets us gear the respective cleaning process to the customer's specific product.

Barrel finishing

A wide selection of plastic or ceramic abrasive products and compounds enables us to provide the type of surface treatment that is perfectly tailored to each product - adapted to suit the part's geometry and meet drawing specifications in exact compliance with the customer's wishes.

A special process also permits the barrel grinding of finished parts.

We use environmentally friendly, high-performance, constantly monitored, semi-automatic barrel-finishing systems. Closed water circulation protects the environment.

Electroplating

For surface finishing parts across selective sections or all over, we draw on the services of long-standing external partners who have been provided with the requisite qualifications and audited by us and who finish every product with a degree of precision and in a level highest quality second to none. Any finish can be provided that is achievable in various combinations of electroplating. We can offer the right solution whether you need technical surfaces relevant to further processing, to protect your products from environmental impacts or to improve conductivity.

We carry out all common test procedures, such as layer thickness measurement with defined measuring points or salt spray tests.

Heat treatment

Specific applications or mechanical requirements on a product often demand additional heat treatment after the production process. Proper and dimensionally accurate hardening or tempering requires extensive knowledge and experience - this is available from our external service providers. Precision, not only after stamping!

Module assembly

We shall be pleased to take care of the entire process of assembling ready-to-install modules or systems for our customers. Doing so, we assume responsibility for the quality of all components involved. All on a one-stop-shop basis, on time and with absolute reliability, you can place your trust in our many years of experience.

Depending on assembly complexity, several processing and testing steps will be necessary. However, this is where our aim is always to find the most cost-efficient process and reduce the number of process steps to an absolute minimum by using the highest possible degree of automation and state-of-the-art machines or automatic assembly facilities in combination with innovative tools.

Picking and packing

We understand picking to mean all of the knowledge that is required for packaging parts in the successful way. In consultation with our customers and geared towards the further processing of parts, we define concepts for the most cost-effective packaging system that guarantees damage-free delivery worldwide. Although parts can be shipped in the conventional way as bulk goods or parts in strip form in cartons, blister packaging, dedicated trays, customer small load carriers (SLCs) and tape & reel can also be used. We will be pleased to devise an efficient and individually tailored packaging concept for you.

Packaging otpions

- Reels or layered: we deliver strip-form products on our own reusable reels or layered on pallet, alternatively on customer-specific disposable or reusable packaging.

- Tape & reel: have your components packed in blister tapes for automatic further processing in the correct position. We can cater to various standards or even customise blister taping.

- Small load carriers (SLCs): we follow our customers' standards. The finished parts are packed in individually tailored customer SLCs filled to optimum capacity.

- Cardboard box - disposable packaging: disposable packaging is the inexpensive option for shipping bulk items. Disposable packaging makes a particularly attractive option in cases where reusable packaging is ruled out for hygiene reasons, reprocessing reusable packaging involves too many resources or returning it is too expensive.

- Tray packaging: your products are provided with maximum protection when they are individually packaged in secure and impact-resistant, customised tray packaging. No filling material is needed and contents can be removed by robot with absolute precision.

Your favoured packaging not listed? Please let us know your specific preference and we will be pleased to review the options for providing it.

Take advantage of our comprehensive line-up of logistics services. This comes with a clear mission statement: punctual delivery of your shipments – with timing and packaging tailored exactly to your requirements. The benefit to you: we see our competent export team as a crucial pillar in customer service. Uncompromising logistics! Multilingual members of staff get supplies to your operating bases around the globe and reliably coordinate international forwarders.

OUR QUALITY MANAGEMENT SYSTEM IN COMPLIANCE WITH DIN EN ISO 9001 2015 HAS BEEN IN PLACE SINCE 1996 AND REGULARLY TAKEN FORWARD.

Essentially, our processes comply with IATF 16949, particularly where we can offer our customers additional benefits. We carry out sampling in accordance with PPAP (Production Part Approval Process) or, in specific instances, in line with customer requirements; we clarify this scope of sampling as early as the project planning phase.

We place a main focus on preventive measures and comprehensive advance quality planning. Assisted by an FMEA database developed by ZETKA, project teams ensure that our stamping tools are ready for volume production in five verification/validation stages.

Comprising trained and highly qualified members of staff, our quality department provides our specialist departments with support along the entire process and value chain. Full traceability is ensured by the use of a CAQ system networked across the company.

In production, we set store by high-precision optical and tactile CNC-controlled measuring systems as well as 100% camera inspections with high-resolution video measuring cells directly on the machine. The high-quality systems guarantee measurement results with a very high degree of reproducibility within the measuring equipment's capabilities.

Entries in the IMDS database are obligatory. We ensure compliance with REACH and RoHs by meticulously selecting our raw-material suppliers.

The ZETKA management system on the intranet covers quality management, environmental management in line with ISO 14001, opportunity and risk management as well as occupational health and safety.

Your career at Zetka

ZETKA is a company of the FIR Group, operating successfully both nationally and internationally, and offers jobs with prospects. Whether in development, production, service or sales – we still have a lot to do and are always looking for good people to strengthen our team with a targeted approach.

Training and placements

Cross-border exchange possible

![[Translate to en:] [Translate to en:]](/fileadmin/_processed_/d/9/csm_content-container-img-nachruf_455b982c72.jpg)